Table of Contents

- Executive Summary: Inviscid Flow Visualization Market at a Crossroads

- 2025 Snapshot: Key Players and Innovations

- Core Technologies: From Schlieren to Digital Particle Imaging

- Emerging Applications in Aerospace and Automotive

- Market Forecast 2025–2030: Growth Drivers and Regional Trends

- Regulatory and Industry Standards Update (AIAA, ASME)

- Case Studies: Real-World Deployments and Breakthroughs

- Competitive Landscape: Leading Companies and New Entrants

- Challenges: Technical Barriers and Adoption Hurdles

- Future Outlook: Next-Gen Visualization Tools and Strategic Opportunities

- Sources & References

Executive Summary: Inviscid Flow Visualization Market at a Crossroads

In 2025, the field of inviscid flow visualization stands at a pivotal juncture, driven by rapid advancements in both experimental and computational technologies. Inviscid flow—idealized by the absence of viscosity—plays a critical role in aerodynamics, including aerospace, automotive, and energy sectors. As industries demand more precise and non-intrusive flow analysis, the market is poised for transformative growth, expanding the boundaries of visualization accuracy, speed, and applicability.

Recent years have witnessed a surge in adoption of advanced optical and digital methods, notably Particle Image Velocimetry (PIV), Schlieren imaging, and high-speed laser-based diagnostics. Companies such as LaVision GmbH and Dantec Dynamics continue to refine PIV and Laser Doppler Anemometry systems, offering turnkey solutions with higher spatial and temporal resolution. These tools are increasingly compatible with real-time data acquisition, enabling detailed mapping of inviscid flow fields in wind tunnels and laboratory settings.

Meanwhile, computational approaches—bolstered by high-performance computing and artificial intelligence—are reshaping the visualization landscape. Leading providers like ANSYS, Inc. and Siemens Digital Industries Software have integrated advanced computational fluid dynamics (CFD) modules, allowing for faster, more accurate simulation of inviscid flows. These platforms now feature automated mesh refinement and cloud-based solvers, streamlining the design-to-analysis cycle and making virtual visualization more accessible than ever before.

The next few years are set to bring further convergence between experimental and computational methods. Hybrid environments—where real-time experimental data informs computational models—are gaining traction. NASA and European Space Agency (ESA) are actively developing such integrated systems for aerospace applications, targeting greater fidelity in aerodynamic simulations and reduced reliance on physical prototyping.

Outlook for 2025 and beyond is marked by a push toward automation, miniaturization, and increased usability. Demand from sectors such as urban air mobility, renewable energy, and hypersonic research is expected to accelerate innovation. Enhanced visualization technologies are anticipated to play a pivotal role in optimizing designs, reducing costs, and ensuring safety.

In sum, the inviscid flow visualization technology market is at a crossroads, with new tools and hybrid approaches reshaping industry expectations and technical capabilities. Stakeholders investing in next-generation visualization systems will be well-positioned to capitalize on the accelerating pace of aerodynamic innovation.

2025 Snapshot: Key Players and Innovations

In 2025, inviscid flow visualization technologies are advancing rapidly, driven by growing demands from aerospace, automotive, and research sectors for high-resolution, non-intrusive measurement tools. Inviscid flow—characterized by negligible viscosity and thus minimal internal friction—poses particular challenges for visualization, especially in high-speed or low-density regimes. Industry players are focusing on both digital simulation environments and experimental techniques to capture and analyze these elusive phenomena.

- Schlieren and Shadowgraph Systems: Traditional optical methods such as Schlieren and shadowgraph remain foundational for visualizing inviscid flows, particularly in supersonic wind tunnels. In 2025, companies like LaVision GmbH are delivering modular, high-speed digital Schlieren systems that enable real-time visualization of shock waves and flow discontinuities with unprecedented spatial and temporal resolution. These systems are increasingly coupled with automated image processing and AI-based feature extraction for enhanced analysis.

- Particle Image Velocimetry (PIV): While PIV traditionally targets viscous flows, advanced implementations such as high-speed and tomographic PIV are now being adapted for near-inviscid conditions, capturing subtle flow features at the boundary between laminar and inviscid regimes. Dantec Dynamics continues to push PIV hardware and software integration, emphasizing multi-camera setups and high-repetition-rate lasers for capturing fast transients in wind and water tunnels.

- Numerical Visualization and Digital Twins: Cloud-based computational fluid dynamics (CFD) platforms are enabling “digital wind tunnels” where inviscid flow fields are visualized and manipulated in real time. Ansys and Siemens are notable for integrating high-fidelity inviscid solvers with immersive visualization, allowing engineers to interact with flow fields in VR or collaborative online environments.

- Laser-Induced Fluorescence (LIF) and Advanced Imaging: For specialized applications, companies such as Quantel Laser (now part of Lumibird) are refining pulsed laser systems that, when paired with advanced cameras and sensitive dyes, make it possible to image scalar fields and flow boundaries even in low-density, inviscid regimes.

Looking ahead, the sector anticipates further integration of AI-assisted analysis, miniaturization of high-speed imaging hardware, and cloud-native CFD, making inviscid flow visualization both more powerful and accessible. Cross-sector collaboration—particularly with aerospace primes and research consortia—will likely drive the next generation of hardware and software innovations through 2026 and beyond.

Core Technologies: From Schlieren to Digital Particle Imaging

Inviscid flow visualization has seen significant advancements in recent years, with technologies evolving from traditional optical methods to sophisticated digital tools. Historically, techniques such as Schlieren and shadowgraph imaging have provided qualitative insights into inviscid flows, especially in wind tunnel and aerodynamics research. In 2025, these core methods remain relevant but are increasingly complemented by digital and hybrid approaches that enhance precision, flexibility, and data richness.

Modern Schlieren systems, which visualize refractive index gradients in transparent media, have been refined with the integration of high-speed digital cameras and LED illumination. Companies such as PHOTRON are supplying high-frame-rate cameras capable of capturing complex, transient phenomena in shockwave and supersonic flow environments. The enhanced sensitivity and temporal resolution allow for more granular analysis of inviscid flows, essential in aerospace and defense applications.

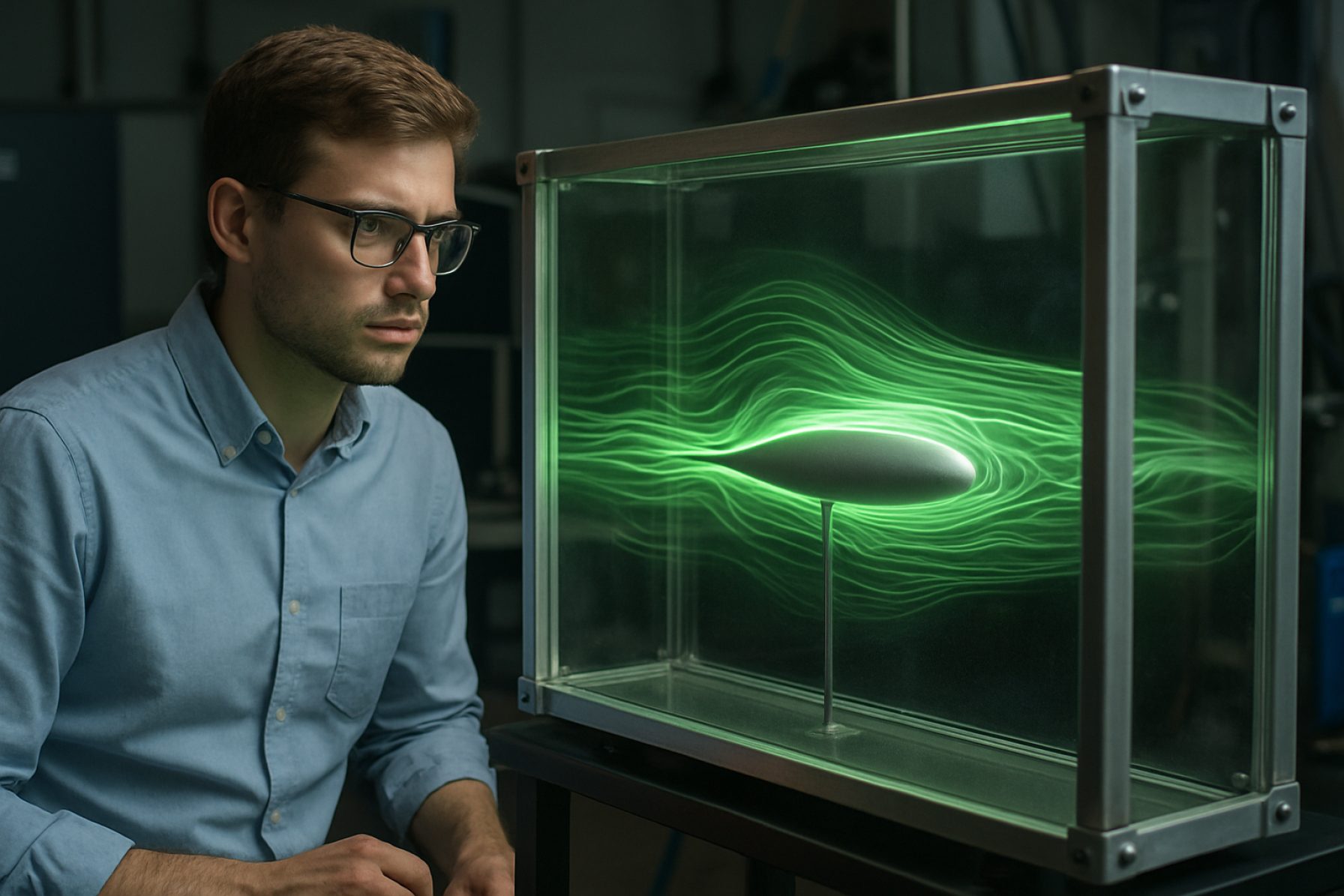

Digital Particle Image Velocimetry (DPIV) has emerged as a leading technology for quantitative flow visualization in both laboratory and industrial settings. DPIV tracks the movement of seeded tracer particles within a flow, utilizing laser sheets and image processing to reconstruct velocity fields. Manufacturers like LaVision have introduced turnkey DPIV systems that integrate laser optics, synchronization modules, and advanced software for near real-time analysis. The systems are widely adopted in research institutions and industry R&D centers, supporting investigations into shock-boundary layer interactions and external aerodynamics where inviscid assumptions hold.

Additionally, the push for increased automation and AI-driven analysis is influencing the landscape. Advanced software suites are being developed to automatically identify flow features such as vortices and shockwaves, reducing manual data processing time and improving reproducibility. Dantec Dynamics is at the forefront, offering software updates that leverage machine learning to extract flow structures and streamline visualization workflows.

Looking ahead to the next few years, the sector is expected to see further integration of 3D visualization and tomographic reconstruction techniques. Companies are investing in multi-camera setups and volumetric imaging algorithms, enabling the capture of three-dimensional flow fields in inviscid regimes. These advances will support not only fundamental fluid mechanics research but also the optimization of aerospace components and high-speed transportation systems, where inviscid flow assumptions underpin much of the design process.

Overall, the fusion of advanced optics, high-speed imaging, and intelligent software continues to push the boundaries of inviscid flow visualization, promising more comprehensive and actionable data for researchers and engineers through 2025 and beyond.

Emerging Applications in Aerospace and Automotive

Emerging applications of inviscid flow visualization technologies are rapidly transforming the aerospace and automotive industries as both sectors pursue higher efficiency, safety, and performance. In 2025, the integration of advanced visualization tools with computational fluid dynamics (CFD) and experimental techniques is enabling engineers to better understand idealized, non-viscous flow behaviors—crucial for optimizing designs where minimizing boundary layer and drag effects is sought.

One of the most significant developments is the adoption of real-time flow visualization platforms that leverage high-speed particle image velocimetry (PIV) and advanced smoke or tracer injection systems. For instance, LaVision GmbH has introduced modular PIV systems capable of capturing instantaneous velocity fields in wind tunnel environments, helping researchers approximate inviscid flow conditions around airfoils and automotive bodies. These systems are increasingly being paired with augmented reality overlays and machine learning algorithms to accelerate interpretation of complex flow structures—an approach under active evaluation by several leading aerospace manufacturers.

Additionally, the aerospace sector is pioneering the use of non-intrusive optical techniques for flight vehicle development. NASA is employing advanced schlieren photography and background-oriented schlieren (BOS) methods in supersonic wind tunnels to visualize shockwaves and flow separation in configurations where inviscid assumptions are valid. These optical methods, when combined with pressure-sensitive paint (PSP) technologies from suppliers like Innovation Scientific, enable high-resolution mapping of surface pressure distributions on prototype vehicles, providing valuable validation data for inviscid flow simulations.

In the automotive industry, vehicle manufacturers are increasingly utilizing digital twin environments, where inviscid flow visualization supports rapid prototyping of next-generation electric and autonomous vehicles. Ansys and Siemens are offering integrated CFD suites that visualize potential flow scenarios, guiding design iterations for reduced drag and enhanced aerodynamics. These tools, often validated by wind tunnel experiments equipped with advanced flow visualization hardware, are expected to become standard in vehicle development pipelines by 2027.

- Real-time PIV and optical methods are streamlining design cycles for next-gen aircraft and vehicles.

- Combined hardware-software solutions are driving a shift toward virtual prototyping and digital validation.

- Industry outlook points to expanded adoption of high-speed, non-intrusive visualization for sustainable mobility solutions and urban air mobility (UAM) platforms.

As inviscid flow visualization technologies mature, ongoing collaborations between equipment manufacturers, software providers, and end users are expected to further enhance fidelity, speed, and accessibility—solidifying their central role in the future of aerospace and automotive innovation.

Market Forecast 2025–2030: Growth Drivers and Regional Trends

The market for inviscid flow visualization technologies is poised for significant growth between 2025 and 2030, propelled by advancements in aerospace, automotive, and energy sectors. Increasing adoption of computational fluid dynamics (CFD) tools and sophisticated experimental visualization methods are key factors driving this expansion. The demand for improved aerodynamic performance and fuel efficiency in both commercial and defense aerospace applications is anticipated to accelerate investments in these technologies. Major aerospace manufacturers are integrating advanced flow visualization solutions to develop next-generation aircraft and unmanned aerial vehicles, leveraging both simulation and experimental approaches for optimal design validation.

Regionally, North America is expected to remain at the forefront, with robust activity from leading aerospace and defense firms and strong collaborations with research institutions. For instance, Boeing and NASA continue to pioneer flow visualization in wind tunnel and CFD research, focusing on laminar flow control and turbulence suppression for commercial and space applications. In Europe, growth is being stimulated by joint projects among organizations such as Airbus and the German Aerospace Center (DLR), which are investing in advanced optical measurement systems and digital simulation environments to support sustainable aviation goals.

The Asia-Pacific region is witnessing rapid adoption due to expanding aerospace manufacturing and R&D. Companies like Commercial Aircraft Corporation of China (COMAC) are integrating high-fidelity visualization and measurement equipment for aerodynamic optimization in new aircraft programs. Additionally, Japanese and South Korean automotive manufacturers are increasingly utilizing inviscid flow visualization for electric and hybrid vehicle design, responding to regulatory demands for energy efficiency.

Technological progress in laser-based and particle imaging techniques is expected to enhance the resolution and accuracy of experimental flow visualization, with suppliers such as LaVision GmbH advancing digital particle image velocimetry (PIV) systems. CFD software advancements by companies like ANSYS, Inc. are making inviscid analysis more accessible and reliable, further bridging the gap between simulation and physical testing.

Looking ahead, the market for inviscid flow visualization technologies is projected to grow at a steady pace, fueled by regulatory pressure for sustainability, the proliferation of digital twins, and the need for real-time data integration in engineering workflows. Regional clusters with strong aerospace, automotive, and energy industries are likely to see the fastest adoption, positioning these technologies as critical enablers of next-generation design and manufacturing innovation.

Regulatory and Industry Standards Update (AIAA, ASME)

In 2025, the regulatory and industry standards landscape for inviscid flow visualization technologies is experiencing notable evolution, driven primarily by advancements in computational capabilities and increased demand for higher fidelity validation in aerospace and mechanical engineering. Key industry bodies such as the American Institute of Aeronautics and Astronautics (AIAA) and the American Society of Mechanical Engineers (ASME) are actively updating their guidelines and standards to incorporate new methodologies and ensure compatibility with emerging simulation and measurement techniques.

- AIAA’s CFD and Flow Visualization Standardization: In early 2025, the AIAA’s Fluid Dynamics Technical Committee signaled a revision of its recommended practices for computational and experimental visualization of inviscid flows, emphasizing the need for interoperability of data formats and reproducibility in both numerical and physical flow visualization. The updated guidelines are expected to better align with the growing use of advanced optical techniques and the integration of digital twin frameworks in wind tunnel experiments. The AIAA’s ongoing collaboration with leading wind tunnel facilities and software providers underpins these standards, with a focus on harmonizing flow field data extraction and presentation (AIAA).

- ASME’s Digital Validation and Experimental Protocols: ASME, through its Fluid Engineering Division, has prioritized the standardization of digital validation protocols for inviscid flow regimes. In its latest committee meetings, ASME has moved to formalize requirements for the use of advanced non-intrusive flow visualization technologies—such as Particle Image Velocimetry (PIV) and Schlieren imaging—in experimental validation of computational models. These standards aim to bridge the gap between numerical inviscid simulations and physical test data, ensuring greater consistency in the reporting and certification of aerodynamic and hydrodynamic systems (ASME).

- Outlook and Industry Engagement: Moving forward, both AIAA and ASME are expected to increase collaboration with manufacturers of flow visualization equipment and software to further refine standard test protocols and support international harmonization efforts. The trend toward open data standards and cloud-based sharing of flow visualization results is likely to accelerate, as organizations seek to streamline multi-site validation and regulatory compliance. Workshops and standards development panels scheduled throughout 2025 and 2026 will continue to address the integration of AI-driven analysis into core regulatory frameworks.

Overall, the regulatory trajectory in inviscid flow visualization is toward greater rigor, interoperability, and digital integration, reflecting both technological progress and the sector’s commitment to verifiable, high-quality aerodynamic analysis.

Case Studies: Real-World Deployments and Breakthroughs

Inviscid flow visualization technologies have seen significant advancements and real-world deployments in recent years, with notable breakthroughs expected to continue through 2025 and beyond. These technologies are essential in industries such as aerospace, automotive, and energy, where understanding high-speed, low-viscosity flow is critical for optimizing design and performance.

One prominent case study is the application of pressure- and temperature-sensitive paint (PSP/TSP) by NASA in wind tunnel testing of next-generation aircraft. In 2023, NASA’s Langley Research Center used advanced PSP coatings to visualize supersonic flow over aircraft models, enabling engineers to map pressure distributions with unprecedented spatial resolution. This non-intrusive technique is accelerating the development of innovative airframe geometries that minimize drag and shockwave formation.

In Europe, the German Aerospace Center (DLR) has deployed time-resolved particle image velocimetry (TR-PIV) for real-time monitoring of inviscid flow in rocket nozzle tests. By integrating high-speed cameras and pulsed laser systems, DLR achieved frame rates exceeding 10 kHz, capturing transient flow structures in detail. These advancements have directly contributed to the optimization of nozzle designs for Ariane and other launch vehicles, improving efficiency and reliability.

Commercial aerospace manufacturers like Airbus are also leveraging computational and experimental visualization. In 2024, Airbus applied digital Schlieren imaging in their transonic wind tunnel facilities, providing detailed visualization of shockwave interactions on commercial aircraft wings. The technology, which uses refractive index gradients to reveal flow features, supports rapid prototyping and design iteration, reducing development cycles for new aircraft.

In the automotive sector, Toyota Motor Corporation has adopted oil-film interferometry to visualize boundary layer transitions in high-speed vehicle testing. This has enabled engineers to refine vehicle shapes for reduced aerodynamic drag, contributing to improved fuel efficiency in upcoming models.

- NASA—Advanced PSP/TSP for supersonic wind tunnel testing (2023–2025)

- German Aerospace Center (DLR)—High-speed TR-PIV in rocket nozzle optimization (2024–2025)

- Airbus—Digital Schlieren imaging for shockwave analysis (2024)

- Toyota Motor Corporation—Oil-film interferometry in vehicle aerodynamics (2023–2025)

Looking forward, ongoing integration of AI-driven image analysis, higher-speed sensors, and advanced laser diagnostics will further enhance inviscid flow visualization. These innovations are expected to drive breakthroughs in vehicle efficiency, aerospace safety, and energy system optimization, cementing the technology’s critical role into the late 2020s.

Competitive Landscape: Leading Companies and New Entrants

The competitive landscape for inviscid flow visualization technologies in 2025 is shaped by the convergence of advanced imaging systems, computational techniques, and integrated hardware solutions. Established players are leveraging decades of expertise in fluid dynamics instrumentation, while new entrants are capitalizing on digital innovation and AI-driven analytics to create more accessible and flexible visualization tools.

Among the industry leaders, LaVision GmbH continues to be at the forefront with its advanced particle image velocimetry (PIV) systems. Their solutions are widely adopted in research and industrial laboratories for non-intrusive, high-resolution measurement of inviscid flow fields, particularly in aerodynamics and turbomachinery applications. In 2024–2025, LaVision introduced next-generation imaging modules with improved sensitivity and temporal resolution, catering to the demand for real-time, large-scale flow mapping.

Similarly, Dantec Dynamics has expanded its product portfolio to include modular flow visualization platforms that integrate laser-based diagnostics, digital cameras, and proprietary software. Their systems are increasingly used for the study of unsteady, high-speed flows in aerospace and automotive sectors, where inviscid assumptions are crucial for early-stage design and validation.

On the software side, ANSYS, Inc. maintains a strong position with its computational fluid dynamics (CFD) suites. The company’s 2025 releases feature enhanced visualization modules that bridge experimental data from PIV and CFD simulations, enabling more comprehensive analysis of inviscid regions in complex geometries. This integration is vital for researchers seeking to validate numerical models with physical experiments.

New entrants in the market are focusing on democratizing access to flow visualization. Startups such as OpenFLUID (developed by INRAE) are promoting open-source frameworks that allow users to simulate and visualize inviscid flows without the need for proprietary hardware. These platforms are gaining traction in academia and among early-stage innovators for their flexibility and cost-effectiveness.

Looking ahead, collaborations between optical component manufacturers, such as Edmund Optics, and system integrators are expected to yield more compact and affordable visualization kits. The competitive landscape is thus expected to shift towards greater modularity, interoperability, and cloud-based data analytics, allowing a broader range of users to perform sophisticated inviscid flow studies in real time.

Challenges: Technical Barriers and Adoption Hurdles

Inviscid flow visualization technologies, essential for advancing fluid mechanics research and aerospace design, continue to face significant technical barriers and adoption hurdles in 2025. Despite recent improvements in hardware precision and computational modeling, several persistent challenges slow widespread implementation and practical utility.

A core technical barrier remains the difficulty of isolating truly inviscid flow conditions in experimental or applied settings. Most laboratory and wind tunnel environments struggle to eliminate boundary layer effects and minimize viscosity-driven artifacts, complicating accurate visualization and measurement. Even advanced facilities, such as those operated by NASA Armstrong Flight Research Center, continue to devote substantial resources to refining test setups to better approach inviscid conditions, yet report ongoing limitations due to instrumentation sensitivity and flow disturbance management.

High-fidelity visualization tools, such as Particle Image Velocimetry (PIV) and advanced Schlieren imaging, require expensive, delicate equipment and highly controlled conditions. Companies like LaVision GmbH—a global supplier of fluid flow imaging systems—have introduced enhanced PIV and laser-based solutions, but the up-front costs and maintenance demands remain a significant barrier for many research institutions and industry users. Additionally, achieving sufficient spatial and temporal resolution to capture subtle inviscid phenomena—such as small-scale vortices or shock wave interactions—often necessitates custom configurations and highly trained operators, further limiting accessibility.

From a computational perspective, the integration of visualization data with numerical simulation frameworks (such as CFD models) is still challenged by discrepancies between real-world measurement and idealized inviscid flow assumptions. Industry leaders like ANSYS, Inc. are working to bridge this gap by developing new data assimilation tools and hybrid simulation-visualization platforms, but the process of validating computational models against experimental data remains time- and resource-intensive.

Adoption hurdles are also apparent in the slow translation of laboratory advances to applied sectors such as aerospace and automotive engineering. Many organizations are hesitant to invest in new visualization systems without clear evidence of cost-benefit and integration compatibility with existing research workflows. To address these concerns, industry consortia such as the Aerospace Industries Association are facilitating collaboration between technology providers, end users, and regulatory bodies, though consensus on standard practices and interoperability is still evolving.

Looking ahead, overcoming these barriers will require continued investment in robust, user-friendly visualization hardware, open data standards, and multidisciplinary training. As more institutions gain access to cutting-edge facilities and as technology providers prioritize scalability and integration, broader adoption is anticipated—but technical and financial hurdles are likely to persist into the late 2020s.

Future Outlook: Next-Gen Visualization Tools and Strategic Opportunities

The landscape of inviscid flow visualization technologies is poised for significant advancements through 2025 and the ensuing years, driven by the convergence of high-speed imaging, computational fluid dynamics (CFD), and digital transformation in aerospace, automotive, and research sectors. A central trend is the integration of advanced laser-based diagnostics with machine learning algorithms to provide real-time, non-intrusive insights into complex, inviscid flow phenomena.

Major instrumentation providers are advancing Particle Image Velocimetry (PIV) and Laser-Induced Fluorescence (LIF) systems with increased spatial and temporal resolution, enabling finer visualization of shock waves and slipstream effects in wind tunnel and free-flight experiments. For instance, LaVision GmbH has unveiled upgraded PIV systems featuring high-speed cameras and synchronized laser illumination, supporting rapid data acquisition and enhanced analysis for aerospace and defense testing scenarios. Similarly, Dantec Dynamics is emphasizing integrated software-hardware solutions to streamline flow field measurements and visualization workflows, anticipating wider adoption in university and industrial research laboratories.

On the computational front, the adoption of GPU-accelerated CFD solvers is transforming virtual flow visualization. Companies such as ANSYS and Siemens Digital Industries Software are advancing simulation suites capable of visualizing transient, three-dimensional inviscid flow fields with fidelity matching experimental observations. These developments are reducing the time-to-insight for R&D teams, facilitating rapid design iterations, and enabling digital twin initiatives for in-situ monitoring and optimization.

Strategic opportunities are emerging through the coupling of physical and virtual flow visualization. Aerospace organizations, including NASA, are piloting hybrid approaches that combine live experiment data with CFD-based augmented reality overlays, enhancing test campaign efficiency and supporting advanced aerospace vehicle designs. The outlook for 2025 and beyond also points to the democratization of flow visualization tools, as cloud-based platforms lower barriers for smaller firms and research groups to access high-end analytical capabilities.

- Continued miniaturization and automation of optical measurement devices are expected, broadening field deployment beyond controlled laboratory settings.

- Interoperability between experimental and simulation data will underpin collaborative R&D, especially for supersonic and hypersonic vehicle development.

- New partnerships between hardware manufacturers and software developers signal a move towards end-to-end flow visualization ecosystems, enhancing user productivity and accelerating innovation cycles.

In summary, the next generation of inviscid flow visualization technologies promises increased accessibility, higher fidelity, and smarter integration, positioning the sector for substantial growth and strategic realignment in the near term.